Annular cutter pilot pins: How they work…

Center hole for pilot pin accurately aligns the cutter, allows for internal lubrication and removes the slug.

The pilot pin allows you to accurately position the cutter. During drilling, the pilot pin retracts and allows internal coolant to reach the cutting teeth.

When the hole is complete, the slug is automatically ejected from the cutter.

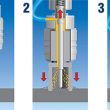

1. Centering: The Pilot pin accurately centers cutter over area to be drilled.

2. Oiling: During drilling, the pilot pin retracts and allows internal coolant to reach the cutting teeth.

The cooling of annular cutters is internal. The internal lubrication is provided through a hole with the help of a pilot pin.

Internal lubrication makes the annular cutter faster and more efficient for deep hole drilling

3. Ejecting: When hole is complete, the slug is automatically ejected from the cutter.